Heavy Fuel Oil (HFO) power plants play a critical role in the marine and energy sectors, providing reliable and cost-effective energy solutions. However, like any complex machinery, HFO power plants require consistent maintenance to ensure optimal performance, safety, and longevity. Regular servicing is not just a recommendation—it’s a necessity. In this blog, we’ll explore why regular servicing is essential for HFO power plants and how it can benefit your operations.

Why Regular Servicing is Crucial for HFO Power Plants

Ensures Operational Efficiency

HFO power plants operate under extreme conditions, leading to wear and tear over time. Regular servicing helps identify and address issues like fuel injector clogging, turbine inefficiencies, or boiler scaling before they escalate. By maintaining peak efficiency, you can reduce fuel consumption and operational costs.Prevents Unexpected Downtime

Unplanned downtime can be costly, especially in the marine and energy sectors where operations run 24/7. Routine maintenance helps detect potential failures early, preventing unexpected breakdowns and ensuring uninterrupted power generation.Extends Equipment Lifespan

HFO power plants are a significant investment. Regular servicing ensures that critical components, such as turbines, boilers, and fuel systems, remain in excellent condition. This not only extends the lifespan of the equipment but also delays the need for costly replacements.Enhances Safety

HFO power plants operate at high temperatures and pressures, making safety a top priority. Regular inspections and servicing help identify risks such as leaks, corrosion, or faulty valves, reducing the likelihood of accidents and ensuring compliance with safety regulations.Reduces Environmental Impact

Poorly maintained HFO power plants can lead to increased emissions and fuel wastage. Regular servicing ensures that emission control systems, such as scrubbers and filters, are functioning correctly, helping you meet environmental standards and reduce your carbon footprint.Cost Savings in the Long Run

While regular servicing requires an upfront investment, it saves money in the long term by preventing major repairs, reducing fuel consumption, and avoiding penalties for non-compliance with environmental regulations.

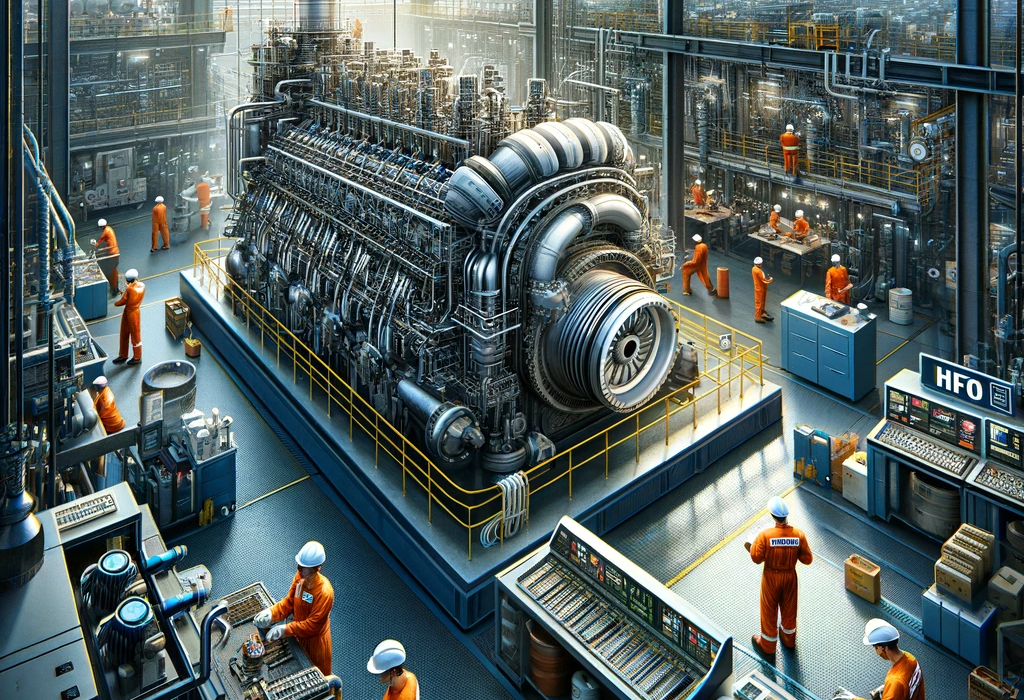

Key Components to Focus on During Servicing

Fuel System: Inspect and clean fuel injectors, filters, and pumps to ensure efficient fuel combustion.

Turbines and Generators: Check for wear and tear, alignment issues, and lubrication needs.

Boilers: Remove soot and scale buildup to maintain heat transfer efficiency.

Emission Control Systems: Ensure scrubbers, filters, and monitoring systems are functioning properly.

Cooling Systems: Inspect pumps, pipes, and heat exchangers for leaks or blockages.

Best Practices for Regular Servicing

Follow Manufacturer Guidelines

Adhere to the recommended maintenance schedule provided by the equipment manufacturer.Use Qualified Technicians

Ensure that servicing is performed by experienced professionals familiar with HFO power plant systems.Implement Predictive Maintenance

Use advanced monitoring tools and sensors to predict potential failures and schedule maintenance proactively.Keep Detailed Records

Maintain a log of all servicing activities, including inspections, repairs, and replacements, to track the plant’s performance over time.

Conclusion

Regular servicing is the backbone of efficient and reliable HFO power plant operations. By prioritizing maintenance, you can enhance performance, reduce costs, and ensure compliance with safety and environmental standards. Whether you’re in the marine or energy sector, investing in regular servicing is a smart decision that pays off in the long run.

At Desert Marine Diesel, we specialize in providing top-notch servicing solutions for HFO power plants. Our team of experts is dedicated to helping you maximize efficiency, minimize downtime, and achieve sustainable operations. Contact us today to learn more about our services and how we can support your power plant needs.