Electricity, a fundamental necessity in contemporary life, serves as the lifeblood of both residential and business domains. The process of electricity generation demands efficiency and reliability, and in this pursuit, Heavy Fuel Oil (HFO) emerges as a crucial player, ensuring the consistent delivery of this indispensable resource.

Understanding HFO

Heavy Fuel Oil (HFO) stands as a hydrocarbon fuel derived from crude oil, the same source that yields lighter hydrocarbon products like diesel and gasoline. Recognized for its cost-effectiveness, HFO is a reliable fuel extensively employed in power generators across the African continent.

Rationale Behind HFO Usage

Remarkably, a single hydrocarbon power plant operating continuously can generate an equivalent amount of energy as 1,000 wind turbines working under the same conditions. Power plants utilizing hydrocarbon fuels, such as HFO, possess the capability to operate autonomously, functioning off the grid during both electricity creation and supply processes. The consistent availability of HFO, coupled with its superior power generation capacity, positions it as a backup fuel for hybrid plants incorporating alternative sources like wind or solar energy.

HFO Power Plants in Action

HFO power plants offer extended reliability, prolonged life expectancy, reduced operational and maintenance costs, and minimal noise levels – prerequisites for seamless round-the-clock operation. While renewable energy technologies advance in cost-effectiveness, power plants fueled by HFO and other hydrocarbon fuels will continue to play a pivotal role in electricity production until their costs are equaled or surpassed.

Empowering Africa through HFO

The African continent, home to numerous developing nations, grapples with energy supply shortages in many regions. Fuels like HFO present a cost-effective and reliable solution for delivering electricity to these areas. In a recent interview, Chris Dalgliesh, a consulting partner at SRK, emphasized the potential of smaller power generation plants utilizing hydrocarbon fuels to contribute to economic development and enhance investment prospects in these regions.

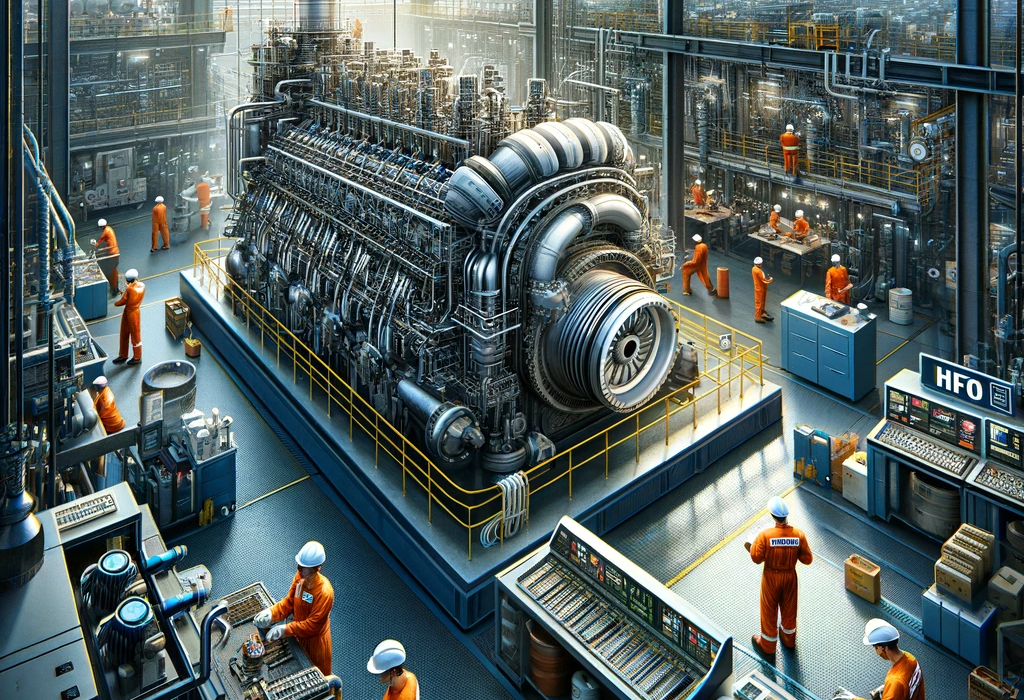

Unveiling the Power Plant Mechanism

Initiating the operation of a power plant involves loading HFO into the system, where a massive furnace heats the fuel until releasing heat energy. This energy is then harnessed in a boiler to convert cold water into steam, a crucial element in the energy creation process. The ensuing transformation of steam into kinetic energy occurs as the steam propels the turbine blades at high pressure and temperature. To optimize turbine efficiency, condensers and a large cooling tower are employed to cool the steam, which is then recycled through the power station to minimize waste.

Generating Electricity from HFO

The final stage in the energy creation process witnesses the conversion of kinetic energy into electricity. A generator, connected to the turbine, transforms the spinning motion into electricity. This electricity is conveyed to a nearby step-up transformer, enhancing its voltage before being transmitted across the country through pylons. A step-down transformer then reduces the voltage to a safer level for use in homes or commercial areas, with underground cables facilitating the final delivery of electricity.

HFO: A Trusted Fuel Option for Power Plants

HFO has demonstrated its feasibility, cost-efficiency, and reliability as a fuel source, driving numerous power stations globally and particularly in Africa. As refining techniques advance, the availability of lower sulfur fuel oils (LSFO) contributes to minimizing the environmental impact associated with this fuel type.